Technology developed at VŠB-TUO is moving into practical use as ABB purchased the license

ABB, a worldwide leader in industrial automation, acquired the robot welding control license from VŠB – Technical University of Ostrava. This technology, created at the Faculty of Mechanical Engineering, is now being implemented in real-world applications. The commercialization process of the scientific outputs was completed in a remarkably short timeframe.

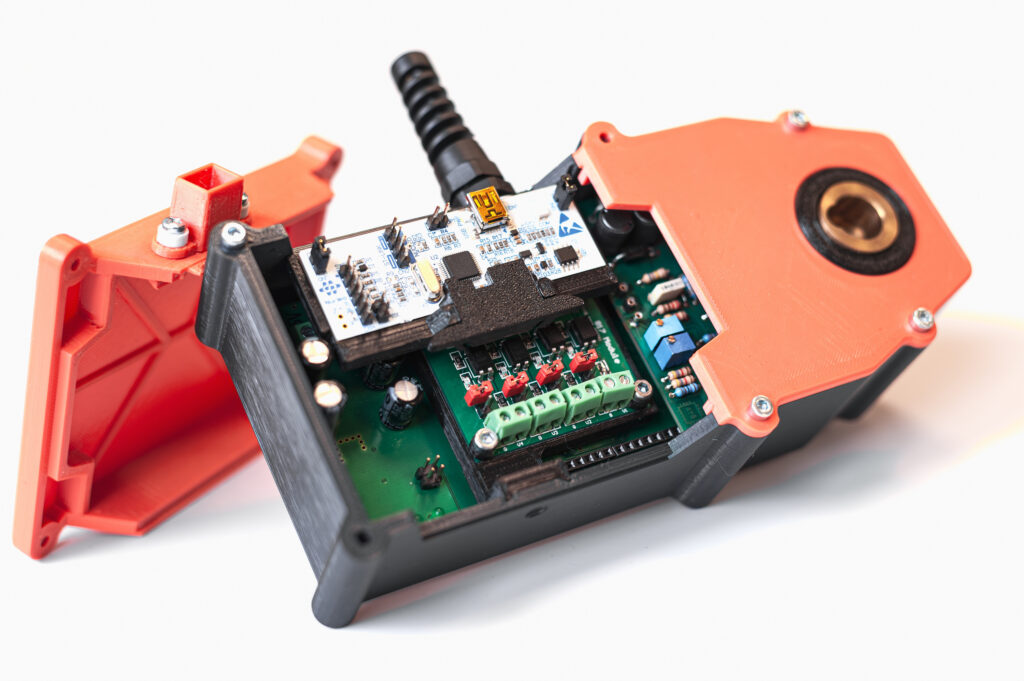

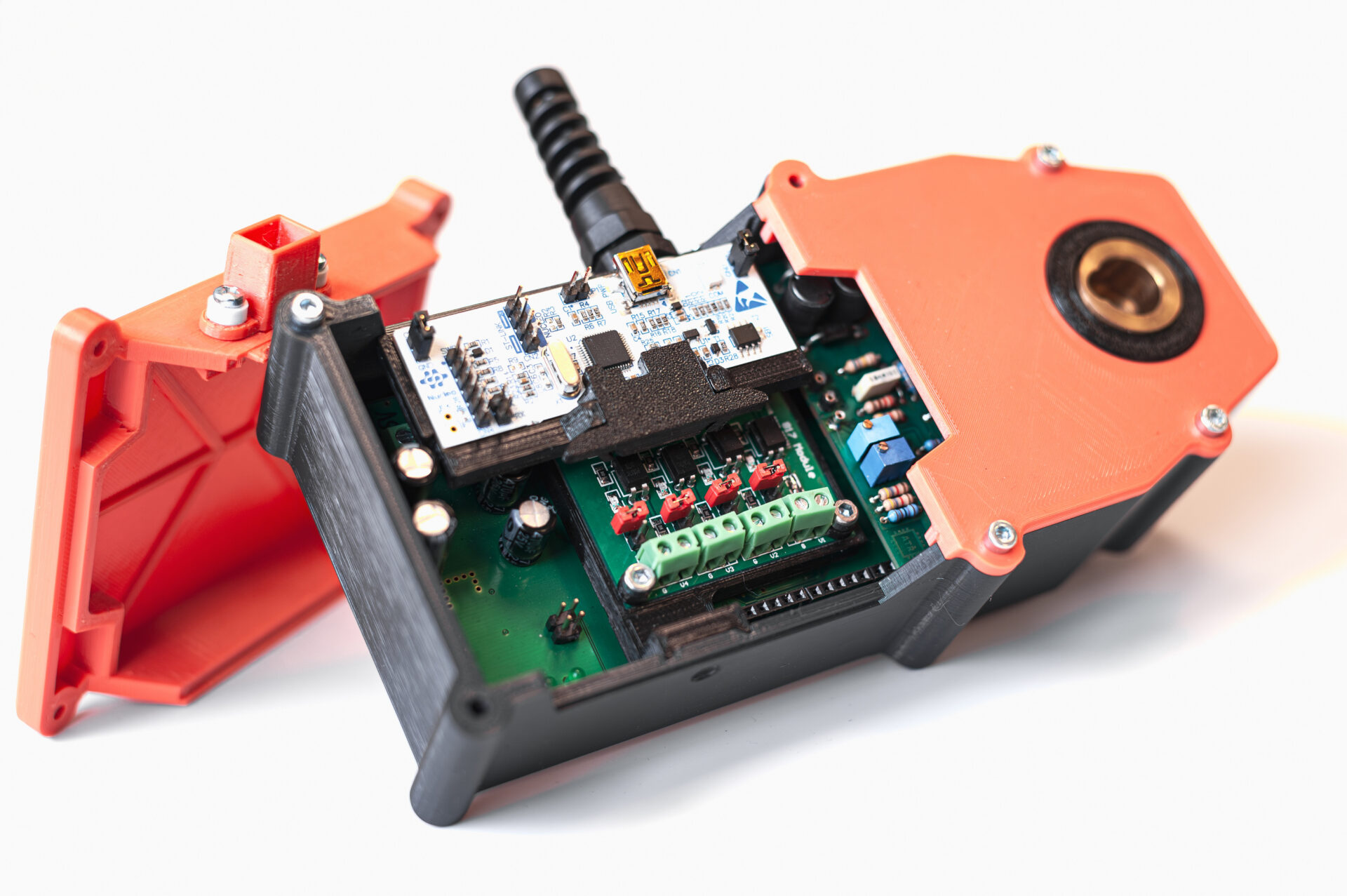

“The technology uses intelligent sensors for continuous monitoring of the welding process and, thanks to advanced analysis of welding current and voltage, can identify weld defects in real time. ABB plans to integrate this technology into its production of robot welding cells, helping its customers increase the efficiency and quality of industrial welding production,” explained David Fojtík, team leader from the Department of Control Systems and Instrumentation at the Faculty of Mechanical Engineering.

A flawed weld can result in various consequences, causing substantial financial losses for the manufacturer, who may need to undertake repairs or create a new product. Therefore, ABB was looking for a cost-effective method to measure robotic weld deficiencies.

“Our solution garnered interest from ABB in the patent and utility model database, leading us to begin negotiations. The proposed solution stood out due to its innovative control approach, overall concept, and active attitude to collaboration. Once the company confirmed that the technology aligned with its needs, we commenced the commercialization process, which involved business discussions, drafting licensing terms, and assessing the technology’s value. Through the collaboration of all parties involved, we accomplished this in just seven weeks, a remarkable achievement within the domestic academic environment,” stated Michal Mokroš from the Technology Transfer Center at VŠB-TUO.

The license is one of the outputs of the REFRESH project, David Fojtík is involved in. “This successful technology transfer confirms the high level of research at VŠB-TUO and its direct impact on industrial practice,” said Igor Ivan, Vice-Rector of VŠB-TUO and Director of the REFRESH. In addition to the revenue generated from the license sale, the university will also receive a portion of the future profits from the technology’s commercial use by end customers.

Robot welding is utilized across various industrial sectors that demand precision, efficiency, and consistency. Its primary applications are found in mechanical engineering, automotive, aerospace, shipbuilding, and energy industries.